Click Pictures to Enlarge

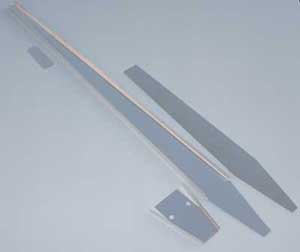

Shown is the empennage kit with fiberglass tips. All skins including the elevator trim tab are preformed. The elevator and rudder skins are predrilled. All of the fin rear spar components are predrilled. All of the steel parts are predrilled.

With the quick build option the vertical fin and horizontal stabilizer rear spars are completed. The elevator and rudder spars are also completed and matched to the stab and fin spars. All hinge parts are installed so the control surfaces are ready to just bolt on. Parts are alodined, zinc oxide sprayed between layers, and all steel parts powder coated to the customers choice of color.